Manufacturing Excellence

for Water Heaters & Water Heating Systems

ISO-Certified Production | Quality-Controlled Processes | Global Standards

At Lucky Brass, we don’t just produce parts — we engineer consistency, reliability, and scale.

Our manufacturing infrastructure has been built over decades to support high-volume production without compromising on quality.

From modern machinery and trained technicians to ISO-compliant processes and rigorous testing protocols, everything is designed to meet the expectations of global OEMs and sourcing teams.

This is the backbone behind our promise:

Precision that performs. Supply that scales. Quality you can count on.

Facility & Production Scale

Our manufacturing facility, spread over 3000sq.ft, operates multiple production lines that collectively deliver over 3000 brass components per month.

With a team of over 45 experienced employees, we have the capability to handle both regular domestic supply and export-grade bulk orders.

Located in New Delhi the facility is fully equipped to support prototyping, pilot production, and high-volume runs with tight delivery timelines.

We maintain consistent stock planning and have built systems to ensure order traceability, packing standardization, and freight readiness.

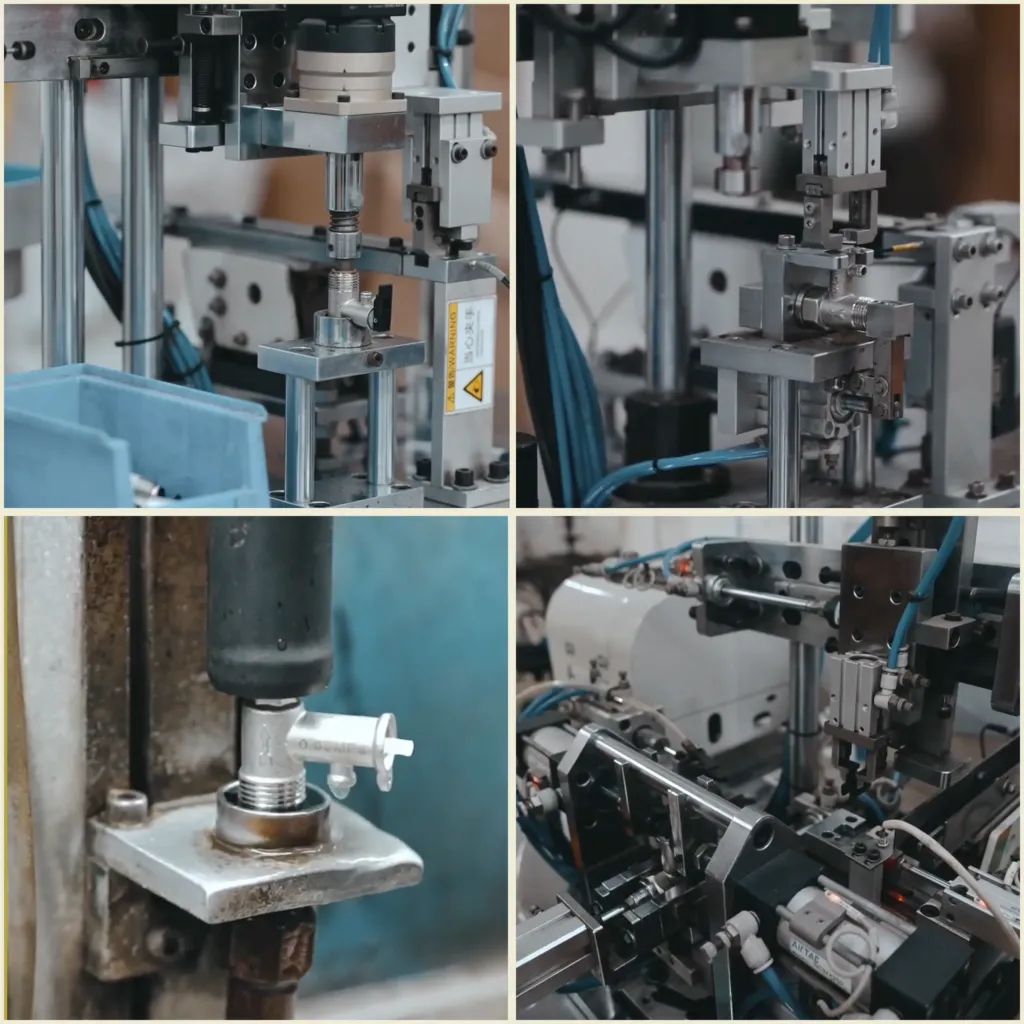

Machinery & Technical Capabilities

Quality through precision engineering.

Our manufacturing facility combines modern equipment with traditional craftsmanship to deliver consistent, high-quality brass components.

Our Capabilities Include:

- Precision machining for accurate dimensions

- Multiple production lines for various component types

- Flexible manufacturing for both standard and custom requirements

- Quality control at every stage of production

We maintain the technical expertise and equipment necessary to meet international standards and customer specifications, ensuring reliable performance in every component we manufacture.

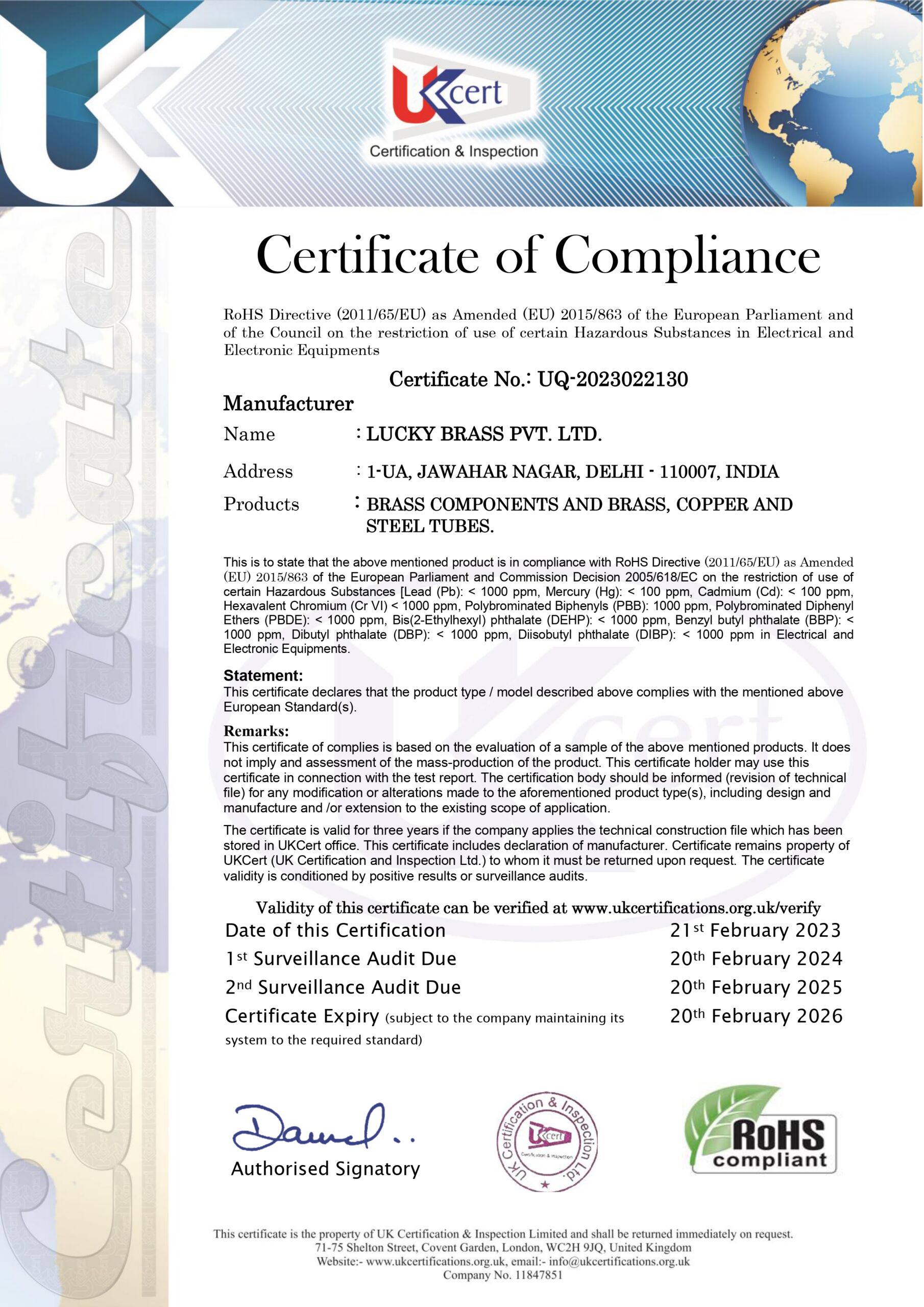

Certifications & Compliance

Our manufacturing unit is ISO-certified, RoHS and CE compliant, and fully equipped for global exports

We follow rigorous batch-level quality checks and maintain detailed, compliance-ready documentation to meet international trade and safety regulations.

All systems are aligned with global quality standards to ensure safe, consistent, and high-performance brass components—built to earn long-term trust.

Work Environment & Culture

We operate out of a clean, safety-compliant, and ergonomically designed facility. Our workers are trained in proper PPE usage and machine safety protocols, and we maintain documentation for all compliance requirements.

Over the years, our team has built a culture of accountability and ownership-ensuring that timelines are met, tolerances are respected, and each shipment upholds the Lucky Brass reputation.

We are also investing in digital traceability tools and exploring automation to increase scale and visibility across the floor.

Our manufacturing systems are built to deliver—at scale, with precision.

If you’ve identified the products you need, we’re ready to fulfill.